If your business does any shipping at all, by now you are well aware of dimensional (“dim”) weight pricing. If your shipping operations haven’t adjusted to the new dim weight standards, now is the time to review and evaluate your product packaging and consider whether you could implement changes for significant cost savings and productivity gains.

Why the Change?

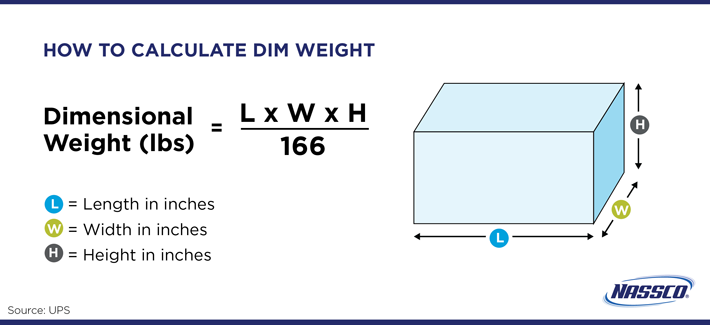

Beginning in 2015, the major carriers implemented volumetric or dimensional ("dim") weight pricing for all ground packages regardless of size. While the rise in e-commerce increased the volume of shipments, most of these products were packaged without regard to density. In billing only by gross weight, lightweight, low-density packages became unprofitable for shippers due to the large amount of space occupied in the carrier relative to actual weight. Dim weight pricing (L” x W” x H” /166) helped solve that problem for the shipper, since customers could be billed whichever is greater, the actual weight or the dimensional weight of a package.

Bright Spots of Dim Weight

While there are benefits to dim weight pricing including reduced fuel and transportation costs, better use of carrier space, and more efficient packaging, you may be experiencing significantly higher shipping costs for your business if you aren’t optimizing your packaging. Companies who assess and update their packaging practices based on the new dim weight pricing model can benefit from reduced costs, improved product protection and greater packaging productivity.

Protect Your Product and Your Bottom Line

Providing adequate protection for contents is essential, but package volume is now an important consideration as well. By using smaller containers packed more economically, many companies can realize considerable savings. Fortunately, Nassco has answers for industries looking to effectively and efficiently package items while also protecting their bottom line.

Cover Your Bases

It's important to use high-quality materials, taking into account strength, cushioning, durability and space consumption. Instapak packaging systems by Sealed Air offer innovative solutions that meet each of these criteria. Machines create customized foam tubes or bags that form to the item, eliminating void in the container. Several different system configurations are available based on business needs, including tabletop, bench top and portable models. The versatility and flexibility of these machines allows for multiple lines to be served with only one system.

Brace for the Best

Blocking and bracing items is essential. For shipping small, delicate items like electronics, circuit boards and replacement parts, Korrvu packaging's highly resilient low-slip film offers unbeatable protection from impact. Retention packaging holds products securely within a frame and film membrane, while suspension packaging suspends products between two layers of film within the airspace of the container. Both options allow products to be shipped in smaller packages without adding significant weight.

Size Matters

Dim weight shipping charges more for mailing a container than a flat envelope, so be sure to always consider the size of your package. Remember, L x W x H /166 is the formula. In most cases it makes sense to use mailer envelopes for items that do not require extra protection. Nassco carries a complete line of cushioned, non-cushioned and rigid protective mailers for appropriate products and other business needs.

Best Practices for Dim Weight Shipping

Below are several tips and guidelines to help you optimize your packaging for dim weight. Many of these can be implemented quickly for immediate cost savings and greater efficiency.

- Choose the appropriate package based on the size of the item, and don't forget mailers as an option.

- Always use high quality materials for your package, considering strength, cushioning, durability and space consumption.

- Be conscious of heavy packaging materials that increase the weight of your package resulting in higher shipping costs.

- Blocking and bracing items is essential. If your item is stationary and unable to move during shipping, it will be less likely to sustain damage.

- Remember that "Fragile" and "Handle with Care" labels do not replace careful packaging.

- Measure the actual outside length, width and height of the container after packaging when determining dim weight, as the measurements provided for boxes are typically inside dimensions of the container and do not reflect exterior dimensions of a package.

- Keep track of your total shipping charges monthly to make sure you're not being incorrectly charged the dimensional weight price.

- If you take returns, educate your customers that if they are returning one item from a multi-order, they should find a smaller package for that one item versus using the original packaging.

- Optimize your packaging using only what you need. Rely on Nassco for help. Call our packaging experts anytime at 800-729-6726.

The above article is a synopsis with commentary of a Sealed Air publication entitled, "Don't Let It Weigh You Down: How to Optimize Packaging to Minimize the Financial Impacts of Dim Weight Pricing and Deliver a Better e-Commerce Customer Experience." Printed with permission of Sealed Air.